As soon as you start learning how to weld, people will start asking questions. Questions such as “Wow, did you really make this?”, or “Why are your eyeballs bloody?”. But the most frequent (and important) question is “Why is this thing not square?“.

For some reason it is not easy to find a welding square here in the Czech Republic – something that would resemble this product from Fireball Tool, or something similar. Being the cheap bastard crafty guy that I am, I decided to build my own.

In general you want something that has a large surface area at least on the perpendicular sides, so that you can actually clamp your work to it – the idea being that as your welds cool down and shrink, all those twisting and bending forces that want to shift your workpiece out of alignment will be countered by the square. So you also want it to be sturdy.

Obviously making the square out of cast iron would be the best (I hear that welding spatter does not stick to it so much), but that is not within my capabilities. I settled for mild steel.

I don’t have a mill, so producing large squarish objects is difficult for me. I decided to go for laser cut parts, that when fitted together would hopefully create and maintain sufficient squareness.

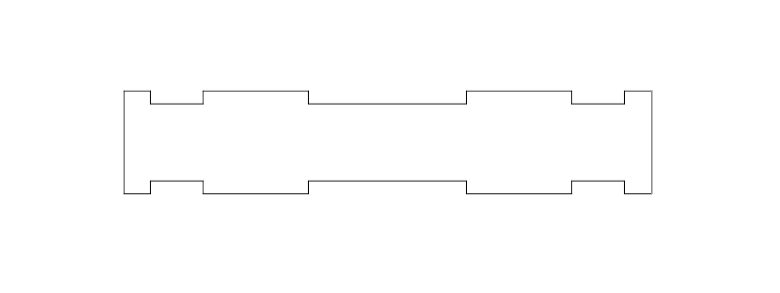

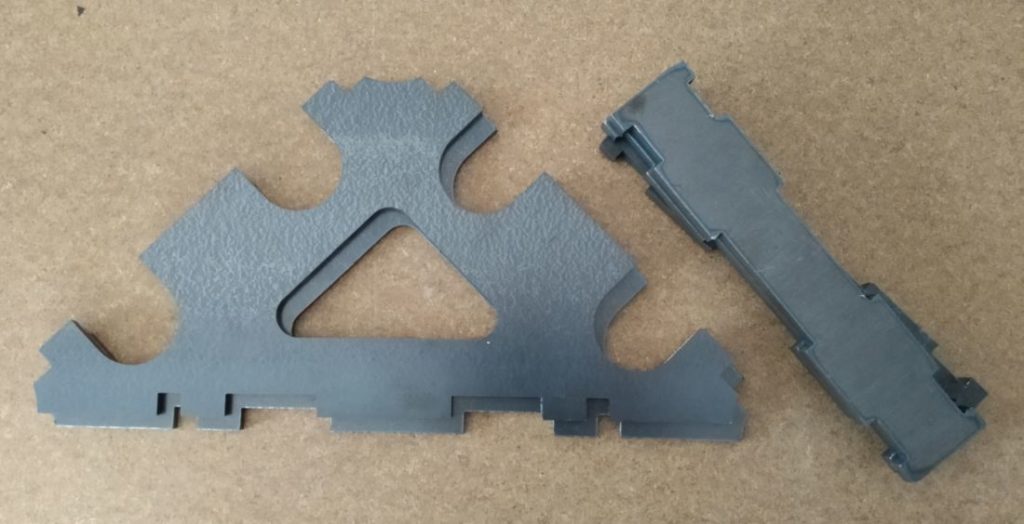

Here is what I came up with:

The whole thing is made out of two 5 mm thick triangles (left), with cutouts on all three sides to accept face plates (right) made out of 10 mm steel. These face plates will then be used to clamp the work piece(s) to. The triangles comprise the “structure” that ensures squareness and stiffness.

I was surprised that the cost for these laser-cut parts wasn’t that high (considering I just wanted these 5 pieces altogether). If you haven’t considered using laser cut parts I highly recommend checking the prices – it might give some unexpeted options in the future.

I welded each triangle to one face plate, and then welded both halves together along with the third face plate. Here is my sophisticated clamping setup. If only I had a welding square to build my square with!

Here is the finished square, sprayed with some black paint:

And here it is in action. Maybe I should have made the cutouts for clamps a little bit bigger – the ones that I own have just enough room, but anything bigger, might have trouble fitting in the whole way.

You can download the dxf files here:

Thanks,

-Pavel